Business

Keiei Japan Co., Ltd. provides on-site, field-oriented solutions primarily for FA and logistics operations, including AGV/AMR introduction support, robot teaching, maintenance services, and engineering support for buy-off of Japan sourced equipment in North America.

AGV / AMR Installation Support

We provide comprehensive support from AGV/AMR selection to installation and adjustment.

We design the optimal models, quantities, and layouts of AGVs/AMRs, based on your actual production lines, loads, and objectives, to help you achieve automation and labor savings.

Robot Teaching

We provide teaching for industrial and collaborative robots.

Our services include flexible adjustments when operating conditions change, such as motion patterns, safety fences, and safety functions.

Maintenance & Support

Through periodic inspections and quick troubleshooting, we help ensure stable operation of your equipment.

We provide continuous support even after installation, including consumable replacements, adjustment work, and improvement proposals.

Engineering Support for Buy-Off of Japan Sourced Equipment in North America

For equipment manufactured in Japan and deployed in North America, we provide on-site support such as installation supervision and progress monitoring.

We share real-time status from local sites with end-users, helping to reduce communication gaps and technical concerns during overseas installation.

Typical Project Workflow

Step 1 – Initial Meeting & Discussion

We carefully listen to your needs and on-site situation, and discuss your issues and goals.

Even if you are unsure where to start, you are welcome to consult with us.

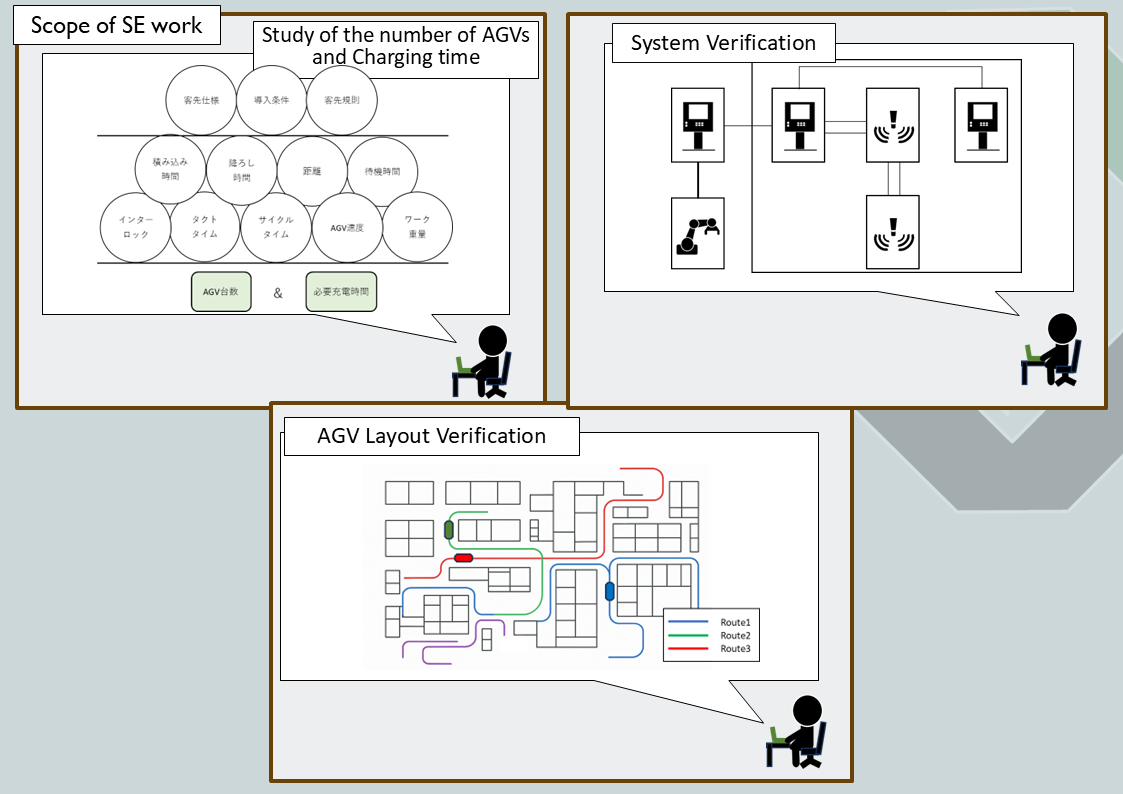

Step 2 – System Design

Based on the information gathered, we design the optimal system configuration, including;

- Overall system configuration design

- Cycle time and capacity calculations

- Layout Verifaication, including traffic flow and safety considerations

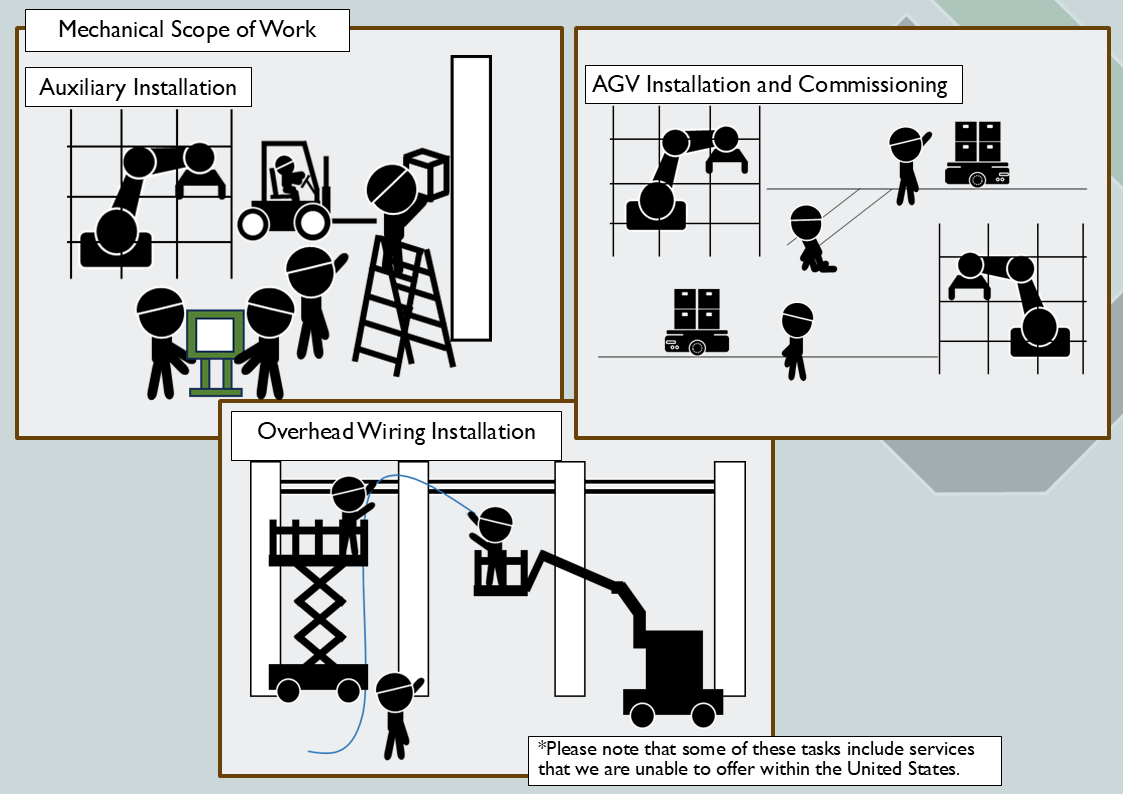

Step 3 – On-site Installation Work

We carry out on-site installation and setup according to the designed system configuration.

[Mechanical]

- Overhead wiring installation

- Layout marking

- Fabrication and installation of auxiliary equipment

- Mechanical adjustments, etc.

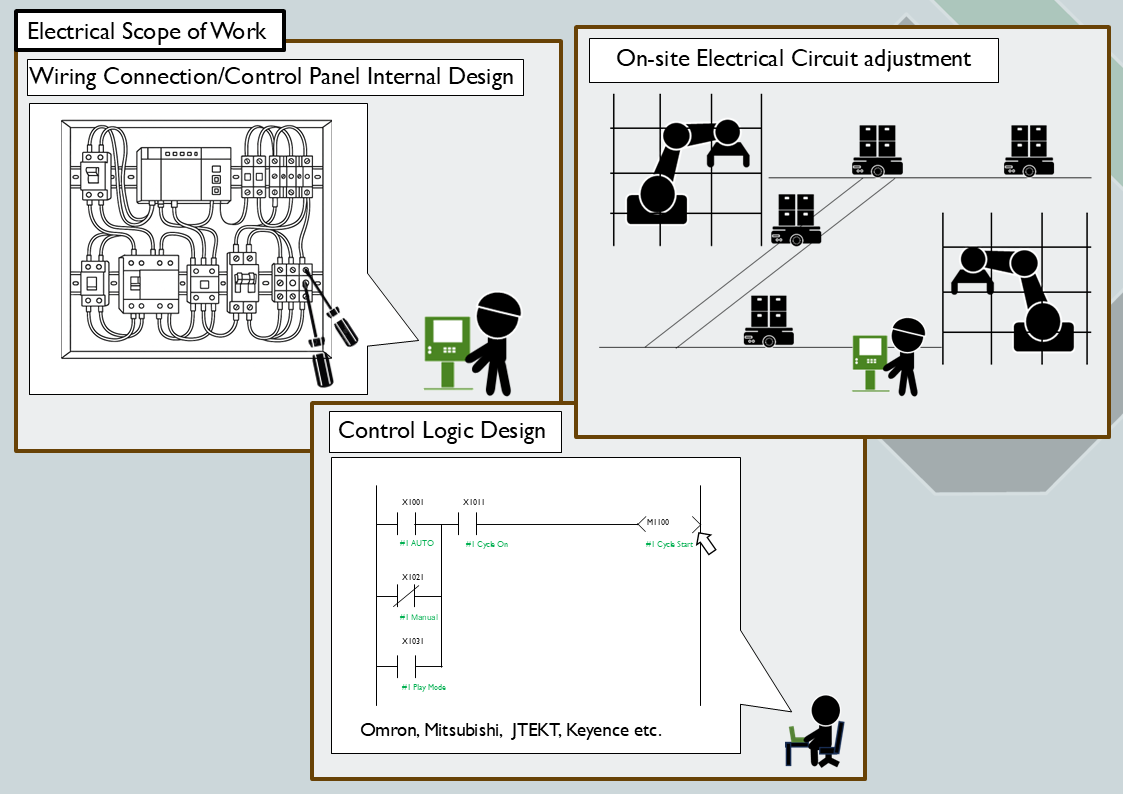

[Electrical]

- Electrical control program design (Omron / Mitsubishi / JTEKT / Keyence, etc.)

- Control panel fabrication

- Sheet-metal component fabrication

- Wiring, connection, and circuit adjustment, etc.

Step 4 – Maintenance & After-sales Service

We provide continuous support and maintenance even after system installation.

Through regular inspections, troubleshooting, and improvement proposals, we help ensure the long-term stable operation of your systems.